Lights

LED lights

LED lights

Lights

LED lights

LED lights

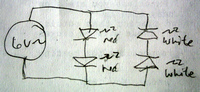

I have this configuration working on 4 bikes. Generally it is two LEDs

in series, each series string in anti-parallel with each other for a

total of 4 LEDs per dynamo. I've even experimented with optionally

adding a supercap across *one* LED in each string to work as a

standlight. If you add a supercap across every LED, your system won't

work optimally and you'll need to resort to a bridge rectifier or other

blocking diodes to regain the advantage.

I have this configuration working on 4 bikes. Generally it is two LEDs

in series, each series string in anti-parallel with each other for a

total of 4 LEDs per dynamo. I've even experimented with optionally

adding a supercap across *one* LED in each string to work as a

standlight. If you add a supercap across every LED, your system won't

work optimally and you'll need to resort to a bridge rectifier or other

blocking diodes to regain the advantage.

I've been using a Shimano HB-NX60 front hub dynamo for a number of years now and have been extremely pleased.

The orange back cap is soft plastic. poke a pair

of holes touching each other with an awl for each wire pair to make an

"8"-like hole for the zip cord to go through without much space around

it to help keep water out.

When mounting, I put the holes facing downwards and the wire leading out

downwards to try to keep water from trickling in.

Since the LEDs are in series, don't cut one of the

wires in the pair as it passes through to the other assembly. The dot

on near the solder pad indicates positive. Use the ribbed or white

striped wire as the negative.

The plastic lens is a stiff clear plastic that comes from "blister pack" packaging.

It is held in place between the screw cap and the gasket.

In behind the LED thermal mounting plate, I usually put a thermal slug,

then usually add wads of bubble wrap to push the assembly forwards into

the blister pack "lens".

Sometimes, with thick enough wire and very snug holes in the back cap

for the wires, the pressure from the wires is enough to hold everything

in place.

The extra black cylinder is a 1F supercap across

the terminals of one LED to make a german standard "standlight".

(previous bike lighting writeup)

Dynamos (Dynohubs)

I'm about to purchase another four Shimano DH-3N72 dynohubs to equip

more bikes.

I never need batteries and they are visible a kilometer away.

More recent designs have added a 1Farad supercap to make a German

standard standlight.

Photos

Light

assembly from a Luxeon Star/O 1Watt LED assembly with collimator fitted

into a 1 1/4" plumbing drain compression fitting (ABS or PVC?). Wire is

16 AWG lamp cord (zip cord) used mostly for mechanical durability since

22 AWG would be fine electrically.

Light

assembly from a Luxeon Star/O 1Watt LED assembly with collimator fitted

into a 1 1/4" plumbing drain compression fitting (ABS or PVC?). Wire is

16 AWG lamp cord (zip cord) used mostly for mechanical durability since

22 AWG would be fine electrically.

Bridge:

+---------------+--------------+

| | |

| | |

+-------+-------+ v +-> ^ +->

| | | |

| | | |

| | | + + + - |

| 6V A/C | +----| |-------+

| | | + + |

| | | |

+-------+-------+ ^ +-> v +->

| | |

| | |

+---------------+--------------+

False bridge:

+---------------+--------------+

| | |

| | |

+-------+-------+ v +-> ^ +->

| | | |

| | | |

| | | + + + - |

| 6V A/C | +----| |-------+

| | | + + |

| | | |

+-------+-------+ v +-> ^ +->

| | |

| | |

+---------------+--------------+

)

Other resources

Acknowledgements

Thank you to

Martin Hicks and the BikeCurrent mailing list

for provoking this writeup.

(C) 2002 Richard Guy Briggs Web

Page last updated by

Richard Guy Briggs

Tue Dec 11 21:24:01 EST 2012